Cold Rolled Coils

With the rolling process made by reducing thickness of the sheets between 0.30-3.00 mm:

- Material tensile strength increases

- Surface quality increases

- Low thickness tolerance is achieved

- The homogeneity of the sheet increases, we can achieve the desired mechanical test values of our customers.

We also cold roll copper, bronze and aluminum.

The products of our customers who supply to the world's largest companies are safely used in countries such as USA, China, Germany, Brazil, Argentina, Italy, France, Australia and South America.

Production Flow

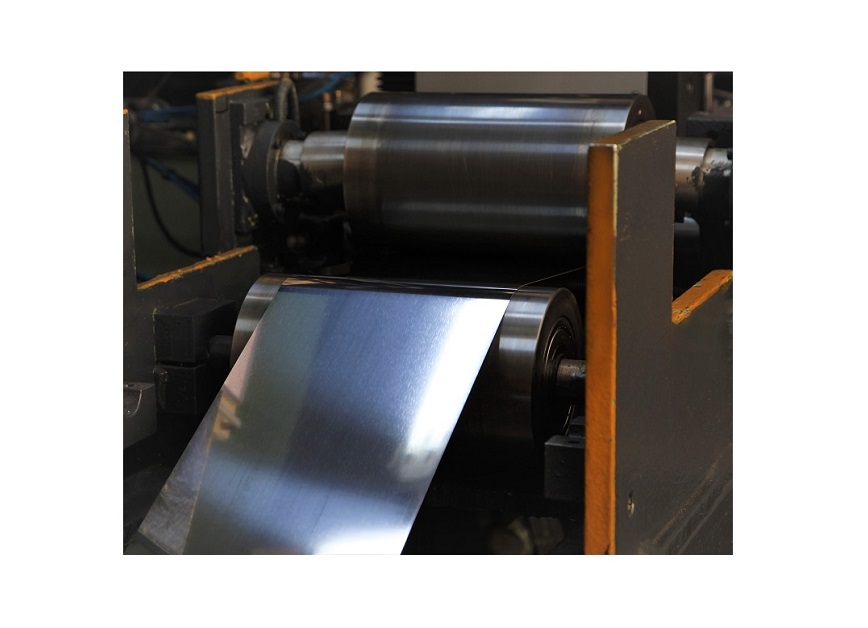

Sheet thicknesses are rolled within the precision thickness tolerance by "Cold Rolling" method between 0.30-3.00mm.

The material surface quality, tensile strenght and mechanical homogeneity increases after rolling.

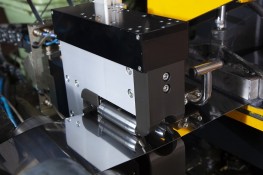

Production can be made with tolerances in the range of +/- 0,005mm with our high-tech test equipment.

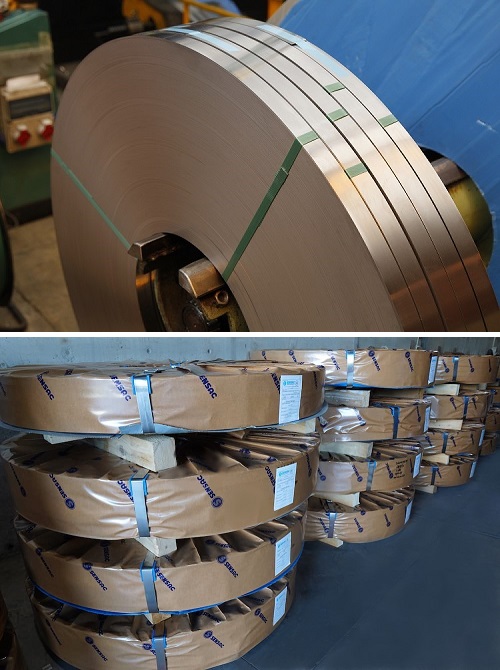

The materials are made ready for shipment by making special packaging in accordance with the customer's request.

Our Capacity

| Decoiler 2 Ton | |

| Coil inlet diameter 400 mm - 508 mm | |

| Thickness 0,30 mm - 3,00 mm |